In today’s fast-paced industrial landscape, choosing the right electric motor is more than just a technical decision—it’s a strategic investment in efficiency and durability. Enter the world of Totally Enclosed Fan Cooled (TEFC) electric motors, where superior engineering meets outstanding performance. But what exactly makes these premium motors stand out from their open counterparts? In this blog post, we’ll dive deep into the myriad benefits of TEFC electric motors—from their robust protection against dust and moisture to their impressive cooling capabilities that ensure longevity and reliability. Whether you’re an engineer seeking optimal solutions or a business owner looking to enhance operational efficiency, understanding why TEFC should be your go-to choice can revolutionize your approach to machinery. Let’s explore how these powerhouse components can elevate your operations to new heights!

Introduction to Premium TEFC Electric Motors

When it comes to powering your machinery or equipment, the choice of motor can significantly impact performance and longevity. Enter TEFC electric motors—an industry favorite for their robust design and reliability. If you’re looking for a way to enhance efficiency while minimizing downtime, understanding what makes these premium motors a top pick is essential. With features that stand up against dust, moisture, and other environmental challenges, TEFC (Totally Enclosed Fan Cooled) electric motors have carved out a niche in various applications across multiple industries. Let’s dive into why choosing a TEFC electric motor could be the game-changer you’ve been searching for!

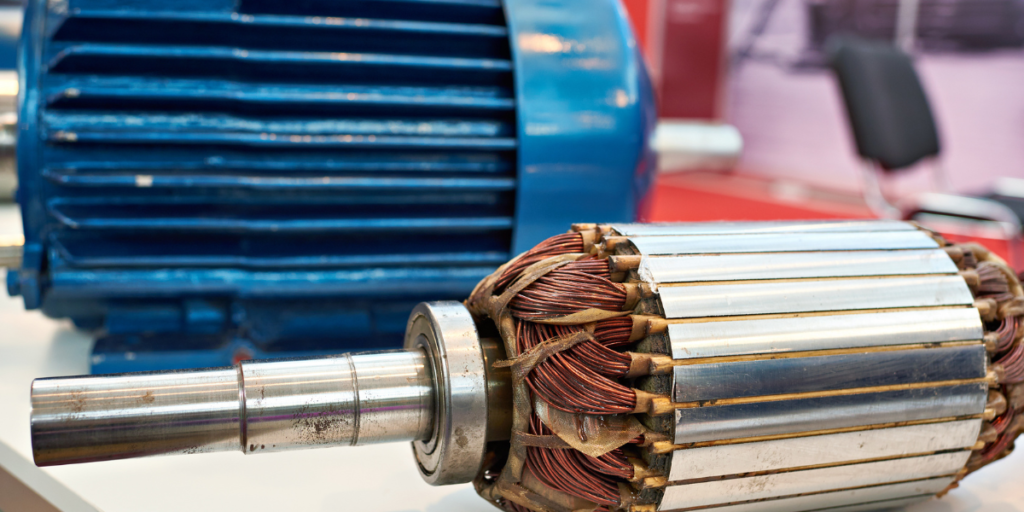

What is a Totally Enclosed Fan Cooled Motor?

A Totally Enclosed Fan Cooled (TEFC) motor is designed with protection in mind. It features a sealed enclosure that prevents dirt, dust, and moisture from entering the motor itself. This design is ideal for environments where contaminants can be problematic.

The fan cooling system plays a crucial role in maintaining optimal operating temperatures. The fan draws air over the exterior of the motor without exposing internal components to external elements. This helps to manage heat effectively, ensuring longevity and performance.

TEFC motors are highly versatile and suitable for various applications. They perform well in both indoor and outdoor settings. Their robust construction makes them reliable choices for industrial machinery as well as HVAC systems.

Differences between Open Drip Proof (ODP) and TEFC Motors

Open Drip Proof (ODP) motors and Totally Enclosed Fan Cooled (TEFC) motors serve distinct purposes in various applications. ODP motors feature ventilation openings, allowing air circulation to cool the motor. This design is suitable for clean environments where moisture and dust are minimal.

In contrast, TEFC motors have a completely enclosed structure, protecting internal components from external elements. The fan mounted on the exterior ensures effective cooling while preventing contaminants from entering.

Another significant difference lies in their durability. TEFC motors tend to have a longer lifespan due to this protection against environmental factors. They are less prone to overheating and damage compared to ODP models.

When selecting between these two types of electric motors, consider your specific application needs. Each has strengths tailored for varying conditions, making them valuable choices depending on operational environments.

Advantages of Using a TEFC Motor

TEFC motors offer a robust design that excels in various environments. Their totally enclosed structure protects internal components from dust, dirt, and moisture. This feature significantly enhances their durability and lifespan.

Another key advantage is the improved cooling system. The fan mechanism efficiently dissipates heat, maintaining optimal operating temperatures even during prolonged use. This prevents overheating issues common in other motor types.

TEFC motors also operate quietly compared to open drip-proof alternatives. Less noise means a more comfortable working environment, especially in settings where sound levels matter.

Furthermore, these motors require minimal maintenance due to their sealed nature. Reduced wear on parts translates to fewer service interruptions and lower long-term operational costs.

Lastly, TEFC motors are versatile and can be used across multiple industries—from manufacturing to agriculture—making them an excellent choice for diverse applications.

Applications and Industries that Benefit from TEFC Motors

TEFC motors are versatile and find applications across various industries. Their robust design makes them suitable for environments where dust, moisture, or corrosive elements are present.

Manufacturing facilities often rely on TEFC electric motors to power equipment like conveyors and pumps. They ensure consistent performance without the risk of contamination from external factors.

In agricultural settings, these motors drive machinery such as irrigation systems and grain handling equipment. Their durability helps maintain operations in challenging conditions.

The HVAC industry also benefits from TEFC motors in air handling units and chillers. These applications demand reliability to maintain optimal climate control.

Additionally, mining operations utilize TEFC motors due to their ability to withstand harsh conditions while delivering high efficiency. Versatility is a hallmark of this motor type, making it indispensable across sectors that prioritize safety and longevity.

Understanding Single Phase vs Three Phase TEFC Motors

When selecting a TEFC electric motor, understanding the difference between single phase and three phase options is essential. Single-phase motors are usually sufficient for smaller applications. They operate well in residential settings and light commercial environments.

On the other hand, three-phase motors excel in industrial scenarios where power requirements are higher. Their design allows for continuous operation with greater efficiency, making them ideal for heavy-duty applications.

Single-phase systems can struggle under load, often leading to overheating or burnout. Three-phase models distribute power more evenly, ensuring smoother performance over time.

Additionally, installation costs may vary significantly between the two types. While single-phase setups might be cheaper initially, investing in a three-phase system can pay off through energy savings and reduced maintenance needs down the line.

Factors to Consider When Choosing a TEFC Motor

When selecting a TEFC electric motor, several factors come into play. First, consider the motor’s power requirements. Match the motor’s horsepower to your application for optimal performance.

Next, think about voltage compatibility. Ensure that the chosen TEFC motor operates efficiently with your existing electrical system.

Another important aspect is environmental conditions. If your application involves exposure to dust or moisture, a TEFC motor provides better protection than its open counterparts.

Don’t overlook efficiency ratings as well. Higher efficiency motors can lead to significant energy savings over time.

Lastly, evaluate the installation and maintenance needs associated with different models. Some may require specialized fittings or regular servicing schedules that could impact overall costs and convenience in operation.

Maintenance and Care Tips for TEFC Motors

Proper maintenance is key to maximizing the lifespan of your TEFC electric motor. Regularly inspect the motor for any signs of wear or damage. This includes checking electrical connections and ensuring that no debris has accumulated around the fan.

Cleaning should be a priority. Dust and dirt can hinder performance, so make it a habit to wipe down surfaces with a soft cloth. For tougher grime, use mild soap and water—avoid harsh chemicals that could harm components.

Lubrication is crucial as well. Ensure bearings are adequately lubricated according to manufacturer guidelines, which helps reduce friction and heat buildup.

Lastly, monitor operating temperatures during usage. If you notice abnormal readings, investigate potential issues promptly to prevent costly repairs or downtime later on. Consistent attention to these details will help ensure reliable operation for years ahead.

Cost Comparison of TEFC Motors vs Other Types of Electric Motors

When considering electric motors, cost is a crucial factor. TEFC motors typically come with a higher initial price tag compared to Open Drip Proof (ODP) or other types like split-phase motors. Their robust design and durability justify the investment.

While upfront costs may be steep, TEFC motors often prove more economical over time. They require less maintenance due to their sealed construction, which protects internal components from dust and moisture. This can lead to lower operational expenses in the long run.

Additionally, TEFC motors boast higher energy efficiency ratings than many alternatives. This translates into reduced electricity bills, especially for heavy-duty applications running continuously.

Considering these factors provides a clearer picture of value rather than just sticker price. Investing in a premium TEFC motor means fewer breakdowns and longer service life, making them an appealing choice for various industries.

Conclusion: Why Choose Premium TEFC Electric Motors?

When considering the best options for your electric motor needs, premium TEFC electric motors stand out. Their robust design and reliable operation make them a smart choice for various applications across different industries. With protection against dust, moisture, and foreign particles, TEFC motors can operate efficiently even in harsh environments.

Their durability ensures minimal downtime due to maintenance or repairs—a crucial factor in production settings where every minute counts. The ability to work effectively under continuous duty further enhances their appeal.

Choosing a TEFC motor means investing in technology that balances performance with longevity. This investment not only reduces operational costs but also boosts overall productivity levels. Whether you’re looking to enhance efficiency in manufacturing or seeking reliability for HVAC systems, the advantages of premium TEFC electric motors are clear.

With all these benefits combined—protection from environmental factors, improved energy efficiency, reduced noise levels—and a wide array of applications available, it’s easy to see why so many businesses prefer this type of motor over others on the market today. If you’re aiming for optimal performance and dependability in your operations, consider making the switch to a premium TEFC electric motor—you won’t regret it.